Integrating robotic welding technology into your manufacturing process can significantly transform your business operations. While it's often recognized for cutting down labor costs, robotic welding brings a multitude of other advantages that go beyond financial savings. These systems enhance safety, improve product quality, and boost overall productivity, providing manufacturers with a competitive edge in the market. Although manual welding remains suitable for certain types of welds, especially those requiring intricate techniques, repetitive and straightforward welding tasks can be more efficiently handled by robots. By automating these processes, businesses can eliminate inefficiencies such as downtime, inconsistencies, and material wastage. Robotic welding systems outshine manual welding in almost every aspect of production. Here are some of the standout advantages: Robotic welding is not just about saving money; it introduces critical efficiencies into the manufacturing process that manual methods cannot replicate. These systems are designed to optimize workflows and drive business growth through enhanced productivity and superior results. A recent example highlights how a manufacturer specializing in metal pallets and skid systems utilized a customized robotic welding solution to address production challenges. Their existing manual processes struggled to meet military-grade welding specifications within acceptable timeframes, causing bottlenecks that threatened profitability and expansion plans. By transitioning to automated welding solutions, this company successfully streamlined their operations and scaled production in line with rising demand. For a deeper dive into their journey, explore the detailed case study from Genesis Systems Group. As industries evolve, embracing advanced technologies like robotic welding becomes essential for maintaining competitiveness. Companies that adopt these innovations position themselves not only to survive but thrive amidst growing market demands. Investing in automation isn't merely about efficiency—it's about creating opportunities for sustainable growth and long-term success. Disposable Food Box Production Line Disposable Food Box Production Line,Disposable Lunch Box Making Machine,Disposable Foam Plates Machinery,Plastic Disposable Lunch Box haiyuanmachinery , https://www.foamfoodboxmachine.comHow Robotic Welding Scales Production and Grows Your Business

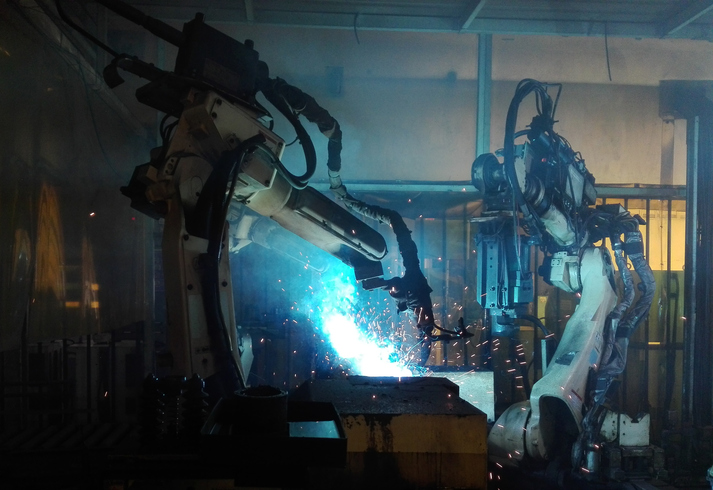

Why Robotic Welding Outperforms Manual Methods

Growing Your Business with Robotic Welding

How Robotic Welding Scales Production and Grows Your Business

# How Robotic Welding Revolutionizes Production and Drives Business Expansion

## The Power of Automation in Welding