Milling Services for Metal Parts,Precision Brass Machining,Brass Metal Milling Parts,Brass Cnc Machining Service Mianyang ZHIWELL Electronics Co.,Ltd , https://www.micrommf.com

The Cost of Quality – A Solar IE’s perspective

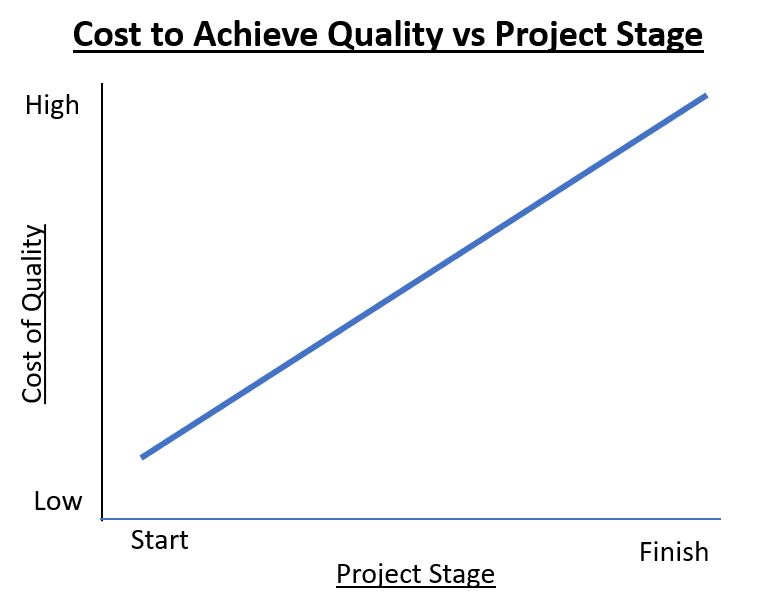

There's a widely recognized business principle known as the "Cost of Quality." This concept illustrates a sliding scale where the closer a project gets to completion, the more expensive it becomes to address quality issues.

Take a look at this image below, which visually represents the idea:

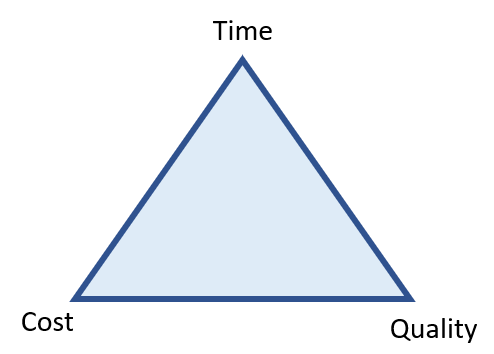

Quality in any project can be measured in terms of time (schedule) and/or cost ($$$). Project management textbooks often refer to these as the "triple constraints," depicted in the classic triangle diagram:

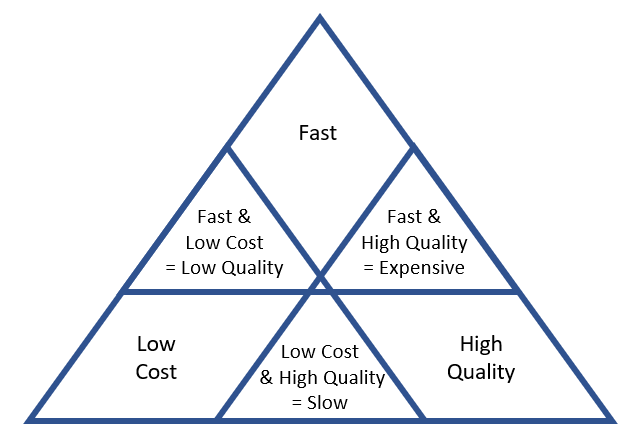

The traditional wisdom here is that you can optimize two aspects but must compromise on the third.

All solar projects go through a design and construction phase that needs to balance time, cost, and quality. As an Independent Engineer (IE), we always aim to avoid compromising on quality just because the project ran out of time or funds—yet, this is frequently the situation when we conduct our reviews later in the project lifecycle.

**The Problem with Conducting an Independent Engineering Review Late in the Project**

Developers typically engage engineers to mitigate risks and ensure quality, usually towards the end of the project's installation phase, as a final approval of both design and installation.

By this stage, addressing risks or quality issues results in greater sacrifices in either time or cost since the allocated budget and timeline have already been utilized:

- Design is finalized.

- Materials have been purchased and installed.

- Labor hours have been spent on installation.

- Performance guarantees for generation are already set in the contracts.

The later a quality issue is identified during design or construction, the higher the price tag in terms of time and/or money to rectify it.

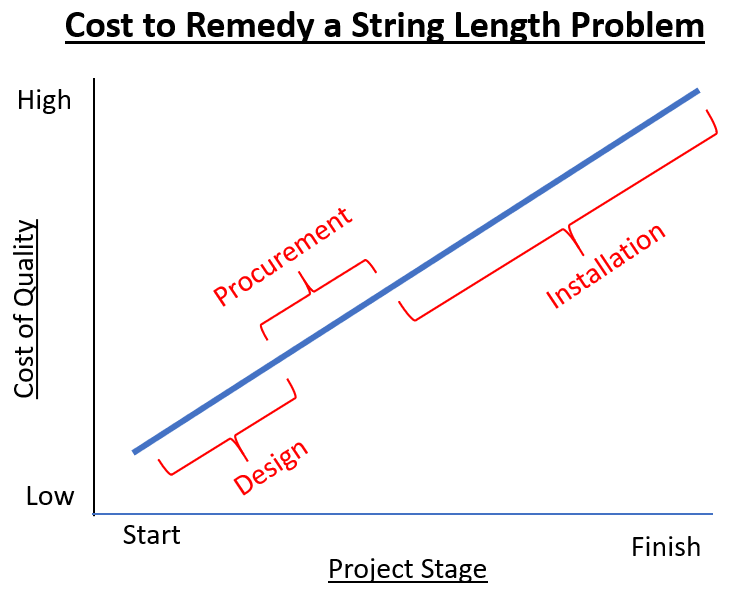

**An Example of the Cost of Quality: Related to a String Length Miscalculation**

There was an error in the voltage calculations, necessitating a reduction in string length. Depending on when the mistake was detected and corrected, there were three possible outcomes:

1. **Design Phase**: The issue could be addressed by revising the design to the correct string length and racking table dimensions. While this might require additional effort from the engineer, it would have negligible impact on cost and schedule.

2. **Procurement Phase**: Once equipment has been ordered, adjusting the string length could influence inverter selection (based on the number of string inputs) or table size. This might mean returning equipment, reordering it, or redesigning the system in a less-than-ideal way to accommodate the existing equipment. Reordering equipment could delay the project, or the design might need to be adapted at an increased cost.

3. **Installation Phase**: After the strings are connected, correcting the string length would involve dismantling and reinstalling the conductors. It might also lead to mismatched table sizes, requiring additional time and cost for inter-row jumpers. This would likely delay substantial completion, increase rework costs, and create a suboptimal design that could complicate operations and maintenance.

**Minimizing the Triple Constraints of Time, Cost, and Quality**

When owners and lenders hire an Independent Engineer, the triple constraints of quality, time, and cost still apply. However, the relationship between these factors changes significantly based on when the review occurs.

- **Early IE Review**: Identifying problems early minimizes the cost and time required to resolve them. Stakeholders appreciate the IE catching all issues, as they can be fixed with minimal impact on cost or schedule.

- **Late IE Review**: Performing technical due diligence at the end of the project results in the highest costs and delays to address quality concerns. Stakeholders often express disappointment that the IE found so many quality issues.

Some argue that "it's the EPC's responsibility to cover the expenses of fixing problems," which may hold true for certain direct costs. However, all stakeholders face increased overhead, time, meetings, calls, disputes over liquidated damages, and so on. EPCs are also more likely to push back on some IE recommendations, leading to many suggestions being overlooked or shortcuts taken due to the high costs involved.

**Conclusion**

Having an IE conduct their review early in the project lifecycle adds significant value to the project.

The later the IE review occurs, the more it becomes a mere "check-the-box" exercise, diminishing the value of the IE review.

If you're going to invest in an IE, get the most out of it by involving them early in the project.

---

This approach ensures that potential issues are caught and resolved before they escalate into costly problems, ultimately saving both time and resources while enhancing overall project quality.