Precision Machining Parts,Cnc Precision Machined Parts,Stainless Steel and metal Parts,Steel Precision Machining Parts Mianyang ZHIWELL Electronics Co.,Ltd , https://www.micrommf.com

The Cost of Quality – A Solar IE’s perspective

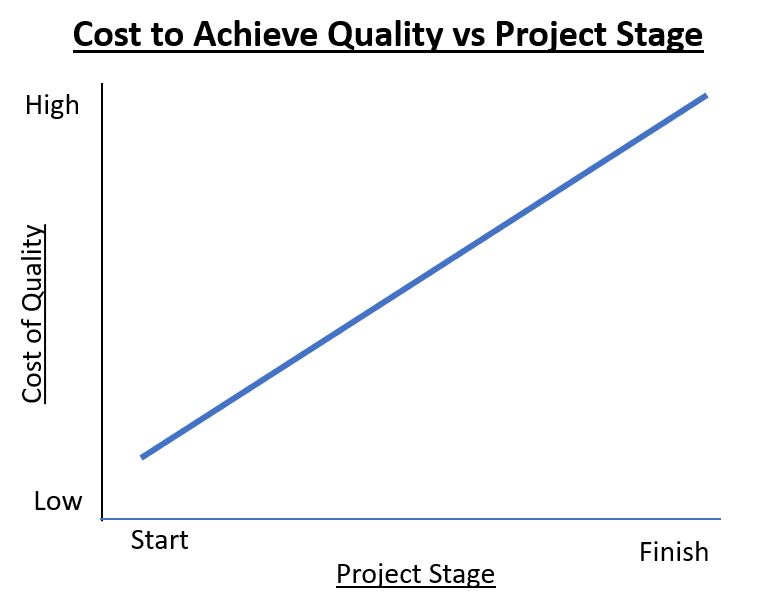

There's a famous business axiom known as the "Cost of Quality." This principle operates on a sliding scale, indicating that the closer a project gets to completion, the more costly it becomes to address quality issues.

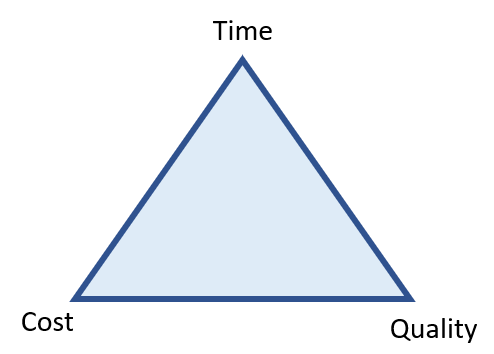

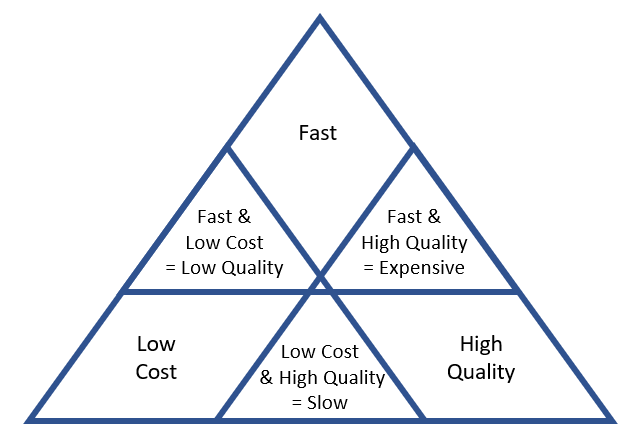

Quality, in this context, manifests itself in terms of time (schedule) and/or cost ($$$). Project management literature refers to these as the "triple constraints," symbolized by the widely recognized triangle:

The conventional wisdom suggests that you can optimize any two factors, but the third will inevitably suffer.

Every solar project goes through a design and construction phase that necessitates balancing time, cost, and quality. As an independent engineer (IE), we always aim to prevent any compromise in quality due to time or financial constraints. Unfortunately, this often happens when we conduct our reviews later in the project lifecycle.

**The Problem with Conducting an Independent Engineering Review Late in the Project**

Developers typically bring in engineers to mitigate risks and ensure quality, often as the installation nears its conclusion. This serves as the final approval for both design and installation.

However, addressing risks or quality issues at this stage usually results in sacrifices in either time or cost since the allocated budgets have already been spent:

- Design is finalized.

- Materials have been procured and installed.

- Installation labor has been utilized.

- Generation performance guarantees are embedded in the contract.

The later a quality issue is identified during the design and construction phases, the higher the price tag in terms of time and/or money to restore quality.

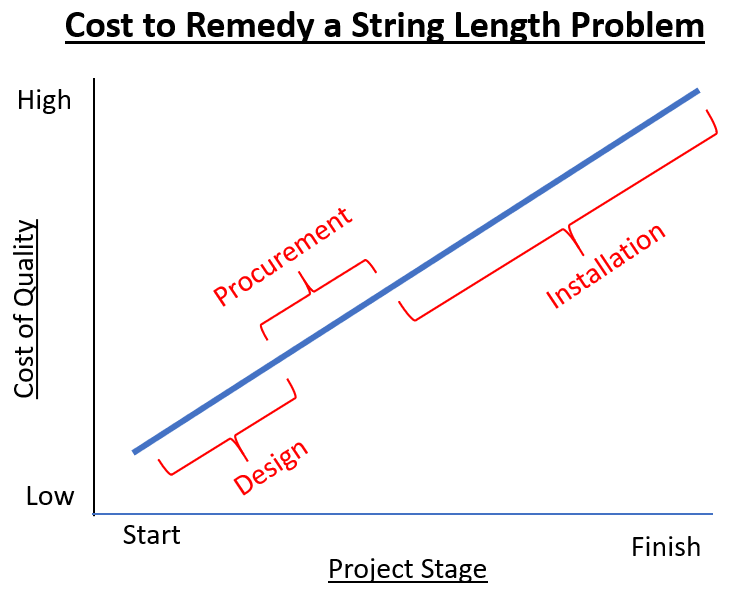

**An Example of the Cost of Quality: A String Length Miscalculation**

There was an error in the voltage calculations requiring a reduction in string length. Depending on when the mistake was detected and corrected, the outcomes varied:

1. **Design Phase**: The issue could be resolved by redrawing the design to the correct string length and rack table size. Although it demands additional effort from the engineer, it has negligible impact on cost and schedule.

2. **Procurement**: Once equipment is ordered, a change in string length might affect inverter selection (number of string inputs) or table size. Equipment may need to be returned, reordered, or the design needs to be adjusted in a less-than-ideal way to accommodate the existing equipment. This could lead to delays if equipment needs to be reordered, or incur additional costs to make the design compatible with the available equipment.

3. **Installation**: If the strings are already wired, correcting the string length would require uninstalling and reinstalling the conductors. It might result in mismatched table sizes, necessitating extra time and cost for inter-row jumpers. This could delay substantial completion, incur rework costs, and create a less optimal design that may complicate operations and maintenance.

**Minimizing the Triple Constraints of Time, Cost, and Quality**

The triple constraints of quality, time, and cost apply when owners and lenders hire an independent engineer. However, the balance between quality and time/cost differs significantly.

- **Early IE Review**: If problems are identified early, the cost and time required to resolve issues and achieve the desired quality are minimized. Stakeholders appreciate the IE catching all issues, as it can be addressed with minimal impact on cost or time.

- **Late IE Review**: Performing technical due diligence at the end of the project incurs the highest cost and time to fix quality issues. Everyone is frustrated with the IE for finding so many quality issues.

Some might argue, "It's the EPC's responsibility to cover the expenses of fixing problems," which may hold true for certain direct costs. However, all stakeholders face increased overhead, time, meetings, calls, disputes over liquidated damages, etc. EPCs may also be more resistant to some IE recommendations, leading to many suggestions being overlooked or shortcuts being taken due to high costs.

**Conclusion**

Having an IE conduct their review early in the project lifecycle adds significant value to the project.

The later the IE review occurs, the more it becomes a mere "tick-the-box" exercise, diminishing the value of the IE review.

If you're going to invest in an IE, get the most value by involving them early in the project.

In summary, the cost of quality highlights the importance of early intervention in project management. By catching issues early, stakeholders can avoid costly corrections later in the process, ensuring better project outcomes overall.