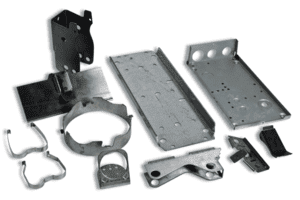

At ESI, we understand the unique challenges that come with metal stamping in various industries. Our mission is to help clients reduce the cost of their stamped metal parts without compromising quality. With over 30 years of experience, we’ve continuously evolved our engineering and manufacturing capabilities, leveraging the latest automated systems to deliver precision and efficiency. Much of our expertise comes from working on safety-critical components for the automotive industry, where reliability, speed, and performance are essential. If you're looking to cut costs while maintaining high-quality standards, here are three key areas to focus on when optimizing your stamped metal parts: The choice of material plays a significant role in the overall cost of metal stamping. Harder materials may require more energy and time to form, which increases production costs. However, there are often alternatives that offer similar mechanical properties at a lower price. For example, switching to a softer or more malleable material can reduce machining time and tool wear, ultimately saving money. It’s also important to consider current market prices and whether your design can accommodate a less expensive option without sacrificing performance. By carefully evaluating your material choices, you can achieve cost savings while still meeting all necessary quality and structural requirements. This is especially useful if the minimum standards for your part have changed over time, allowing you to use more cost-effective options without risking functionality. Tooling is one of the most significant factors affecting both the cost and efficiency of metal stamping. Even small changes in tool design can lead to major differences in production time and expenses. Complex features such as sharp corners or notches can increase wear on the die, leading to more frequent maintenance and downtime. Simplifying your design where possible can reduce tooling complexity and improve long-term performance. For instance, round holes are generally easier and faster to produce than square ones. By rethinking your design, you can eliminate unnecessary complexity and avoid costly retooling. Additionally, regular maintenance is crucial to extending the life of your dies and minimizing unexpected breakdowns. If certain features are unavoidable, consider implementing a more aggressive maintenance schedule to prevent issues down the line. As demand for your components grows, it becomes even more important to optimize your production strategy. Larger volumes allow for streamlined designs that are easier to manufacture, reducing both time and cost. If you're using prototype designs, now is the time to look for opportunities to simplify and refine them for mass production. Raw material and finishing costs can vary greatly depending on the volume you order. One effective strategy is to place blanket orders over a set period, with smaller releases throughout the year. This approach can help you secure better pricing and reduce per-unit costs. Additionally, reviewing complex features for potential revisions can improve quality control and extend the intervals between tooling maintenance. Understanding your Estimated Annual Usage (EAU) is also critical. Based on your production frequency and volume, there may be different tooling options available, such as multi-cavity molds, that can save money while improving efficiency. You might also consider adjusting the thickness of your material or switching to a more malleable metal, which can reduce both material costs and die wear. In cases where production volume exceeds expectations, you may need to invest in additional tooling. It's always best to communicate your projected volume early on, so your supplier can plan accordingly and avoid delays or extra charges. Reducing the cost of your stamped metal parts doesn’t mean sacrificing quality. By focusing on material selection, tooling design, and production planning, you can significantly lower expenses while maintaining performance. At ESI, we specialize in helping clients achieve these goals through expert engineering and advanced manufacturing solutions. We work closely with our clients throughout the entire process to ensure that their metal stamping needs are met efficiently and economically. Whether you’re looking to optimize an existing design or start a new project, our team is here to help. Contact us today to request a quote and see how we can support your business.

Industrial grade Ammonium Chloride is a white powder or granular crystalline form, odorless, salty, and refreshing. Easy to absorb moisture and clump, soluble in water, soluble in glycerol and liquid ammonia, insoluble in ethanol, insoluble in acetone and ether, sublimated at 350 ℃, aqueous solution shows weak acidity. Mainly used in batteries, electroplating, dyeing and weaving, casting, medicine, flocking, fluff, chemical intermediates, and other fields.

Industrial Grade Ammonium Chloride TIANJIN LIHE TRADING CO.,LTD , https://www.lihecorp.comMaterial Selection

Tooling Design and Maintenance

Production Volume and Planning

Quality and Cost-Effective Metal Stamping Solutions

Comments are closed