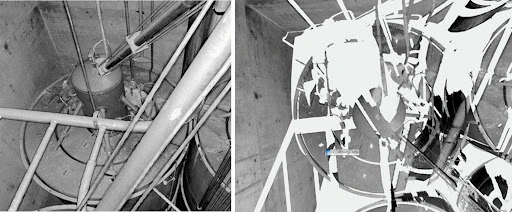

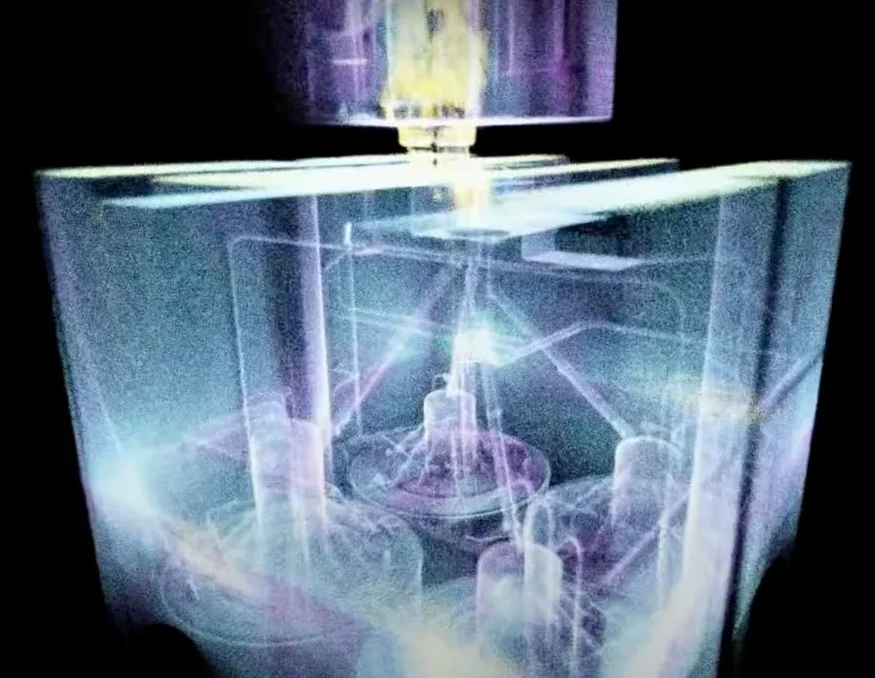

Best Tool for the Job After extensive research, the Idaho Environmental Coalition (IEC), under contract with the Department of Energy (DOE), chose the Elios 3 as the ideal solution for mapping the interior of an irradiated storage vault built in the 1960s. Detailed 3D Mapping The Elios 3 delivered high-resolution 3D maps of the vault, providing the level of detail necessary for planning the safe removal of nuclear waste. Speed In just seven minutes, the IEC collected enough LiDAR data to create a complete 3D map of the vault—marking the successful end of over a year of preparation and research. In the 1950s, the U.S. Department of Energy (DOE) contracted with the state of Idaho to store 4,400 cubic meters (14,436 cubic feet) of nuclear waste at a secure facility known as the Idaho Nuclear Technology and Engineering Center. This waste, called calcine, is a highly radioactive granular solid derived from spent nuclear fuel. It was stored in six underground vaults, each containing bins designed to hold the material. In 2015, the DOE’s contract with Idaho was up for renewal, and the state decided to have the waste removed. This meant the DOE had to find a safe place to store it and develop a method for its retrieval. The Idaho Environmental Coalition (IEC) was tasked with planning the removal and transport of the calcine. Their first challenge was developing a safe and effective method for extraction. The IEC proposed drilling holes into the top of the vaults, then using robotic welding to attach pipes to the bins. A plasma cutter would then be used to open them, allowing the calcine to be suctioned out through the pipes. This remote process minimizes radiation exposure risks for workers. However, the original blueprints lacked the detail needed to determine where to drill. To address this, the IEC initially tried using a handheld LiDAR sensor, but the resulting 3D maps were incomplete due to limited sensor placement. Incomplete 3D maps made with the handheld LiDAR data To create a full 3D map of the vault, the IEC explored several options, including an articulating arm, a helium blimp, and a drone. After evaluating these based on technical risk, budget, and project schedule, they chose Flyability’s Elios 2. However, when Flyability announced the release of the Elios 3, which features a LiDAR sensor, the IEC decided to switch to the new model for more accurate mapping. The IEC built a life-sized replica of the vault to test their equipment and train their drone pilots. They also worked closely with stakeholders to plan every detail of the mission. Watch this video to see highlights from the training: After more than a year of preparation, the day of the flight arrived. The weather was cold and windy, but the vault was warm inside, creating a temperature range from -11°C to over 38°C. The team set up a tent over the entrance to ensure the drone flew indoors, complying with FAA and DOE regulations. A crane was used to lift the heavy cover and open the hatch. The pilot was nervous about flying into the vault, knowing the drone couldn’t be retrieved if it got stuck. Despite the challenges, the flight was a success. In just one seven-minute flight, the IEC collected all the LiDAR data needed for a complete 3D map. A second flight was conducted to gather additional data, which was also successful. The LiDAR data was processed using Flyability’s Inspector 4.0 and GeoSLAM Connect, resulting in detailed and accurate 3D models that met the IEC’s requirements. A screenshot of the 3D model made with the LiDAR data collected in the vault Despite the harsh conditions, the Elios 3 performed flawlessly, collecting all the data needed in just two flights. The IEC team realized several key benefits: An image taken inside the vault alongside the Elios 3's 3D Live Map During a third experimental flight, the drone carried an added weight from a dosimeter. Unfortunately, it became stuck on a piece of angle iron inside the vault. However, the drone transmitted a maximum radiation reading of 7 Gy/h before the battery died. Experts confirmed there were no safety risks. With the successful mapping of the vault, the IEC will now proceed with planning the removal of the calcine using the pneumatic pipe method. All six vaults will eventually need to be emptied, an effort that will take several months of further planning and is expected to begin in mid-2023. The success of the Elios 3 has proven its value in confined space mapping, and both the IEC and DOE plan to use it again for future projects involving remote 3D mapping in hazardous environments. Wafer Container,Wafer Cassette Carrier,Single Wafer Carrier Ningbo Hinix Hardware Industry & Trade Co., Ltd , https://www.hinixpack.comElios 3 Used to 3D Map Irradiated Storage Vault at DOE Site

Key Benefits in a Nutshell

Introduction

Customer Needs

Solution

Results

Conclusion