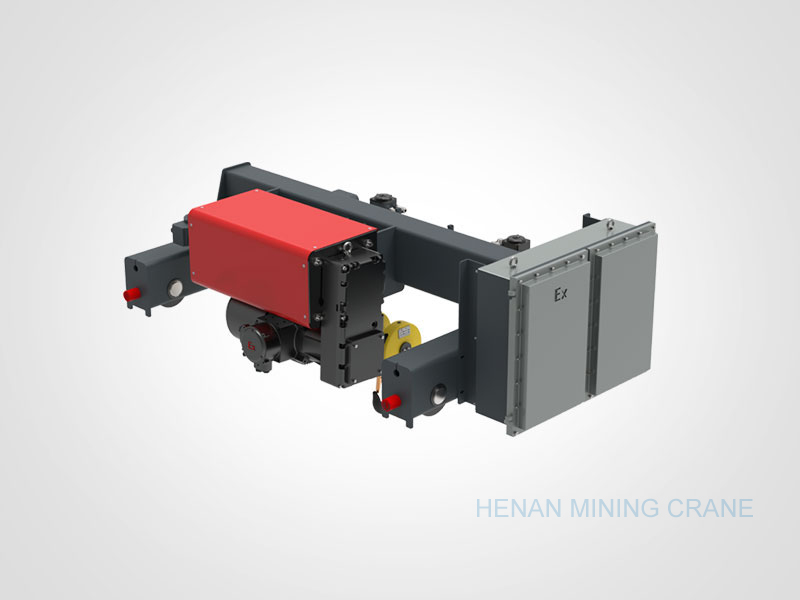

Company Introduction 2. Cement Concrete Block Machine QT10-15 Block Mold Machine Main Advantages 1) Three Bin Batching Plant Function: This is the starting point of the production process. It consists of three loading bins and one weighing bin. Belt conveyors transport materials from the loading bins to the weighing bin. Batching and weighing are controlled by PLC. You can load three different types of materials into the loading bins. 2) JS750 Mixer Function: All ingredients are mixed in this mixer. The mixing time and speed are controlled by PLC. An internal water pump automatically adds water according to the requirements. 3) German Siemens Motor and Japanese Mitsubishi PLC 4. Technical Characteristics of Cement Concrete Block Machine QT10-15 Block Mold Machine : 1). Fully automated block production line, including cluster cars and steam curing cellars, with a high degree of automation. It enables fully automated processes such as batch charging, stirring, forming, transmission, curing, palletizing, and packing. 2). Our machine has passed Europe CE and ISO9001 standards. We use Germany SIEMENS motors and Japanese MITSUBISHI PLC control systems. 3). Three oil cylinders of the same size work simultaneously to ensure consistent density and high-quality blocks. 4). 360° rotating method ensures more uniform material distribution. 5). Moulds are treated with heat treatment technology to extend their useful life. 6). Cooling pumps are installed to cool the oil, ensuring the normal operation of the hydraulic system. 7). Waste recycling tanks are installed to reduce material waste. 5. General Notice 1). Customized color is available upon request. 2). Third-party inspection is available. 3). If needed, the seller can assist the buyer with shipping and insurance. 4). Marking and packaging will be arranged according to applicable international requirements. 5). Warranty: Our block machine is guaranteed for 12 months from the date of commissioning, provided it is used properly. An acceptance act will follow to inspect the application of the equipment. 6). Installation and commissioning are available based on client requirements. One of the key features of the European Standard Wire Rope Hoist is its safety features. These hoists are equipped with various safety devices such as overload protection, emergency stop buttons, and limit switches, which ensure that the hoist stops automatically when it reaches its maximum load capacity or encounters any other safety hazards. The lifting capacity from 1 ton to 60 ton, lifting height from 3 m to 60 m as per customer's different demands, widely are used in Overhead Crane, Gantry Crane, Jib Crane , Port Crane. European Type Hoist,Professional Explosion Proof Lng Hoist,Dead Slow Accurate Moving Lng Hoist,Bnr Explosion Proof Electric Lng Hoist HENAN MAJOR INDUSTRIES IMP. & EXP. CO., LTD. , https://www.henanminingcrane.com

Dongyue Machinery Group is a leading manufacturer of cement brick making machines in China. Our products have been exported to over 60 countries worldwide. We have established overseas offices in India, Indonesia, Vietnam, and Russia. In India alone, we operate 32 fly ash brick making plants, located in cities such as Bhubaneshwar, Coimbatore, Rajkot, Kolkata, Bangalore, and Indore. Two after-sales service centers and spare parts warehouses are available in Ahmedabad and Bhubaneshwar. Our Indian engineers are trained in China and can install the equipment directly on-site.

(1) Fully automatic and hydraulic block making machine, capable of producing various types of bricks by changing molds, including solid bricks, hollow blocks, and paver blocks.

(2) German Siemens motors

(3) Japanese Mitsubishi PLC

(4) Omron travel switch

(5) Molds are heat-treated to increase their lifespan

(6) Certifications: SGS, CE, ISO9001 2008

(7) Mould heat treatment and carburization technology

(8) Strong high-strength steel structure

3. Cement Concrete Block Machine QT10-15 Block Mold Machine Each Part Details

4) Stacker

Â

6. Project Sample

Size (LxWxH)

Pcs/Mould

Pcs/Hr

Â

400X200X200

10

1500-1800

Â

400X100X200

20

3000-3600

Â

225X112.5X60

27

4050-4500

Â

250X60

14

2100-2400

Â

200X100X60

35

5250

Â

200X165X60

20

3000

Â

250x250x60

8

1200-1650

Â

QT10-15 Main Technical Parameters

Dimension of Host Machine

3500×2220×2850mm

Host Machine Power

45.38KW

Â

Moulding Area

1025×810mm

Vibration Force

100KN

Â

Moulding Period

15-25S

Mixer Model

JS750

Â

The Size of the Pallet

1350×900×30mm

General Water Consumption

12T/every day

Â

Weight of the Host Machine

14T

Voltage

380V

Â

The European Standard Wire Rope Hoist consists of a motorized drum that is connected to a wire rope. The wire rope is wound around the drum, and as the drum rotates, the rope moves up or down, lifting or lowering the load. The hoist also includes a lifting mechanism, which can be electric or manual, and a control system that allows the operator to control the hoist's movements.

In conclusion, the European Standard Wire Rope Hoist is a reliable and safe lifting equipment that is widely used in various industries. Its adherence to the European standard ensures that it meets the highest level of safety, reliability, and performance, making it an ideal choice for any lifting application.

Cement Concrete Block Machine Qt10-15 Block Mold Machine

Model NO.: QT10-15

Welding: Carbon Dioxide Welding

PLC: Mitsubishi & Siemens

Motor: Siemens & ABB

AC Contactor: Schneider & Omron

Mold: Heat Treated

Main Material: Sand, Flyash, Cement, Crushed Stone

Oversea Office: India, Indonesia, Vietnam, Russia

Trademark: Dongyue

Specification: ISO9001

Origin: Shandong, China

HS Code: 84748090

1.Cement Concrete Block Machine QT10-15 Block Mold Machine Introduce:

European Type Wire Rope Hoist is a type of lifting equipment that is used to lift and move heavy loads in various industries such as construction, manufacturing, and mining. This type of hoist is designed and manufactured according to the European standard EN 13157, which ensures the highest level of safety, reliability, and performance.

Another advantage of the European Standard Wire Rope Hoist is its versatility. These hoists can be used in various applications such as overhead cranes, gantry cranes, and jib cranes. They are also available in different sizes and capacities, making them suitable for lifting loads of different weights and sizes.